By Nishit Kamdar.Dec 7, 2022

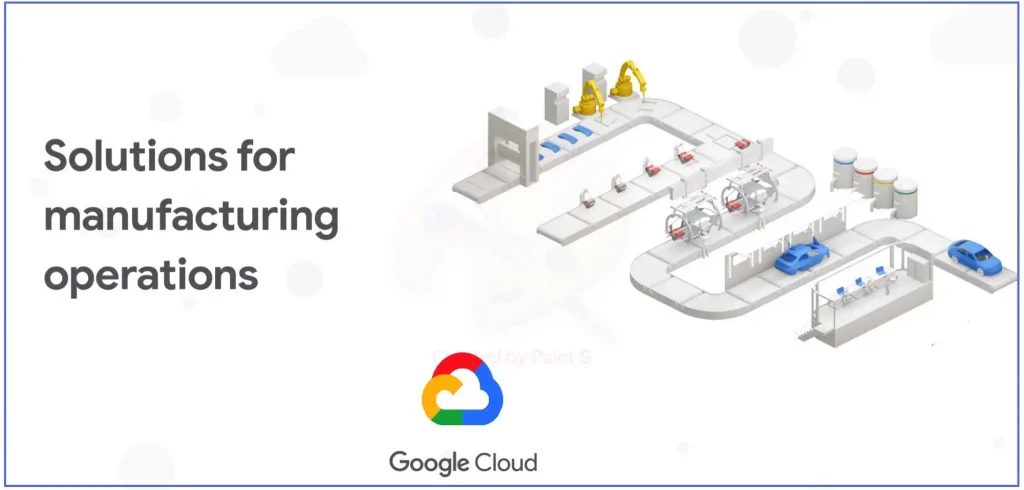

This is Part-1 of the 3-part series on the Google Cloud’s Manufacturing Solution. The focus of this blog will be on the Edge Platform of the integrated suite offered by Google Cloud.

Background:

Industry 4.0 is revolutionising the way companies manufacture, improve and distribute their products. Manufacturers are advancing on their Digital Transformation (DX)ss journey, leveraging the best of technology innovations in Industrial Internet of Things (IIoT), Cloud computing and Analytics, AI and machine learning into their production facilities and throughout their operations to reduce cost, improve operational efficiencies, better products and services, strengthen competitiveness and deliver sustainable growth.

Implemented successfully, these solutions deliver irresistible returns. Across a wide range of sectors, it is not uncommon to see 30%-50%, reductions in machine downtime, 10%-30% percent increases in throughput and 15%-30% percent improvements in labor productivity

The Challenge:

Nearly two thirds of manufacturers already use cloud solutions, according to McKinsey. However, the biggest challenge they face is in scaling Digital Transformation (DX)ss projects from proof of concept to production.

The scalability challenges revolve around the following key requirements:

- IIoT Platform: An Enterprise grade, fully connected, Scalable, Edge-to-Cloud Industry 4.0 platform is required.

- Edge Connectivity: Ability of the Edge platform to connect into all the Industrial assets like sensors, PLCs, SCADA, MES of various make, model and versions is key.

- Scalable Central Data Platform: A central, scalable, Data platform that provides a common data model with built-in data normalization and context-enrichment capabilities.

- Advance AI & Analytics: Ability of the platform to provide integrated Advance Analytics and AI capabilities to build and deploy Machine learning models on to the shop floor.

Introducing Google Cloud’s — Manufacturing Solution:

To ensure manufacturers can scale their Digital Transformation (DX)ss efforts into production, Google Cloud announced a new manufacturing solution suite early this year that focuses on solving the the key factors highlighted above.

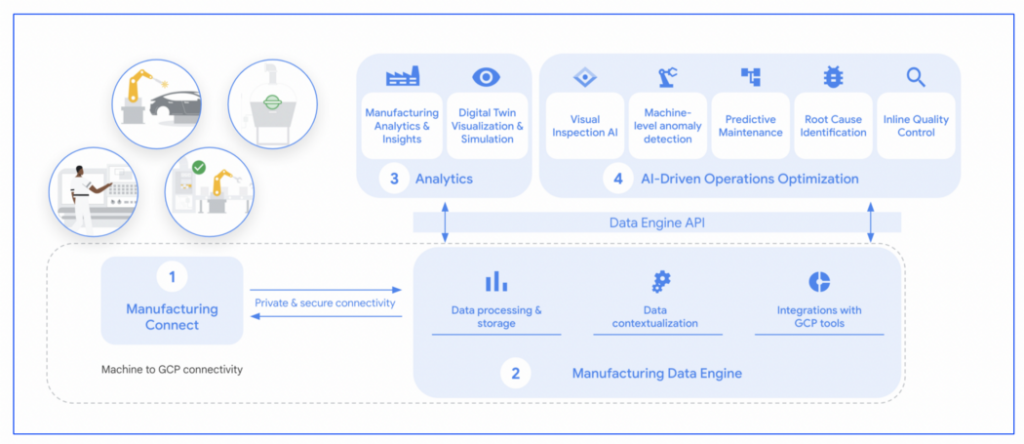

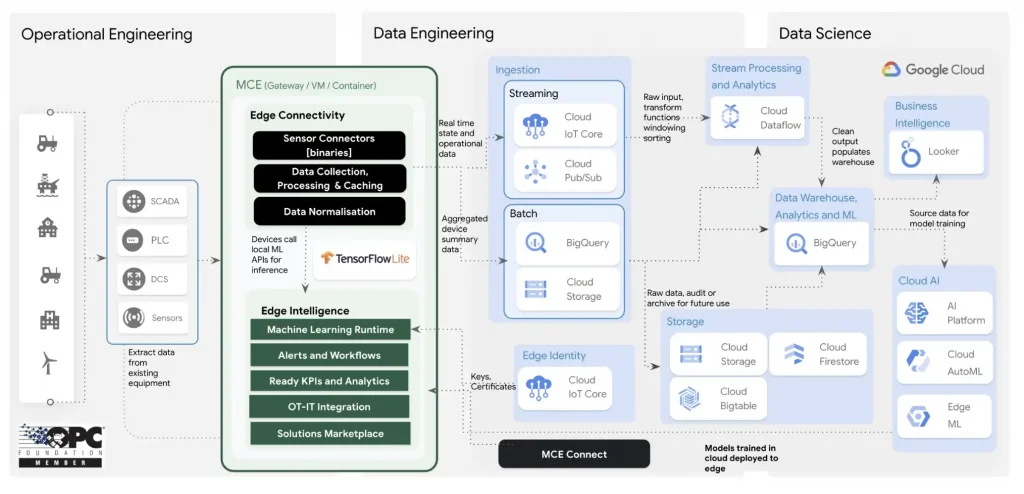

Let’s take a look at the new solutions as we follow the data journey, from the factory floor to the cloud:

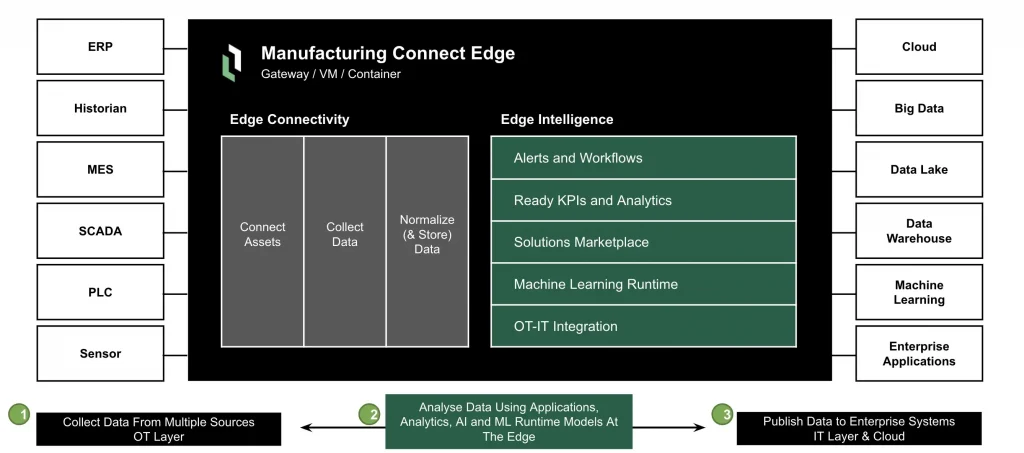

- Manufacturing Connect: is the factory edge platform co-developed with Litmus Automation that quickly connects with nearly any manufacturing asset via an extensive library of 250-plus out-of-the-box supported machine protocols through UI configurations. It translates machine data into a digestible dataset and sends it to the Manufacturing Data Engine for processing, contextualisation and storage. By supporting containerised workloads, it allows manufacturers to run low-latency data visualisation, analytics and ML capabilities directly on the edge.

- Manufacturing Data Engine: is the foundational cloud solution to process, contextualize and store factory data. The cloud platform can acquire data from any type of machine, supporting a wide range of data, from telemetry to image data, via a private, secure, and low cost connection between edge and cloud. With built-in data normalization and context-enrichment capabilities, it provides a common data model, with a factory-optimized data lakehouse for storage.

- Analytics: Built on Manufacturing Data Engine is an out-of-the-box integration with Looker templates that delivers a dashboarding and analytics experience. As an easy-to-use, no-code data and analytics model, it empowers manufacturing engineers and plant managers to quickly create and modify custom dashboards, adding new machines, setups, and factories automatically. The solution enables drill down into the data against KPIs, or on-demand to uncover new insights and improvement opportunities throughout the factory.

- AI-Driven Operations Optimisation: integrates the best of Google AI and machine learning platform and services to solve for key manufacturing usecases like Predictive Maintenance, Machine-Level anomaly detection, Visual inspection etc. These ML models can be trained and deployed seamlessly onto the shopfloor for real-time low latency inference in the matter of weeks.

Lets deep-dive into the Manufacturing Connect solution which is the enterprise grade Edge Platform from Google Cloud.

Edge Platform – Manufacturing Connect

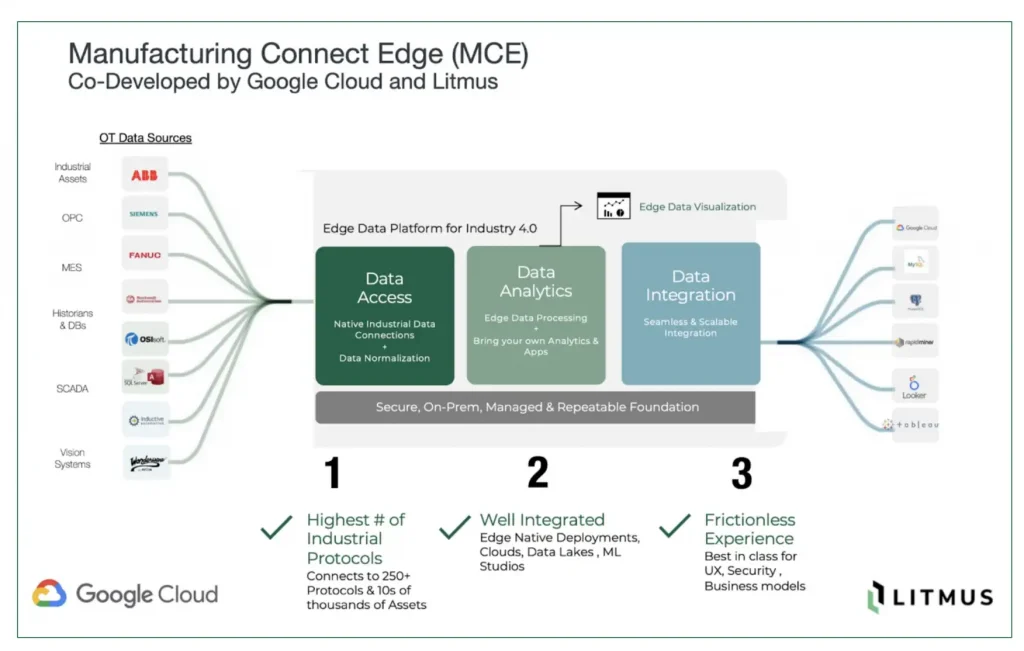

Manufacturing Connect Platform — co-developed by Google and Litmus Automation, provides a highly scalable, purpose-built, edge platform to power Analytics and AI on the factory floors.

Following are the key strengths of the MCE platform:

1. Connectivity:

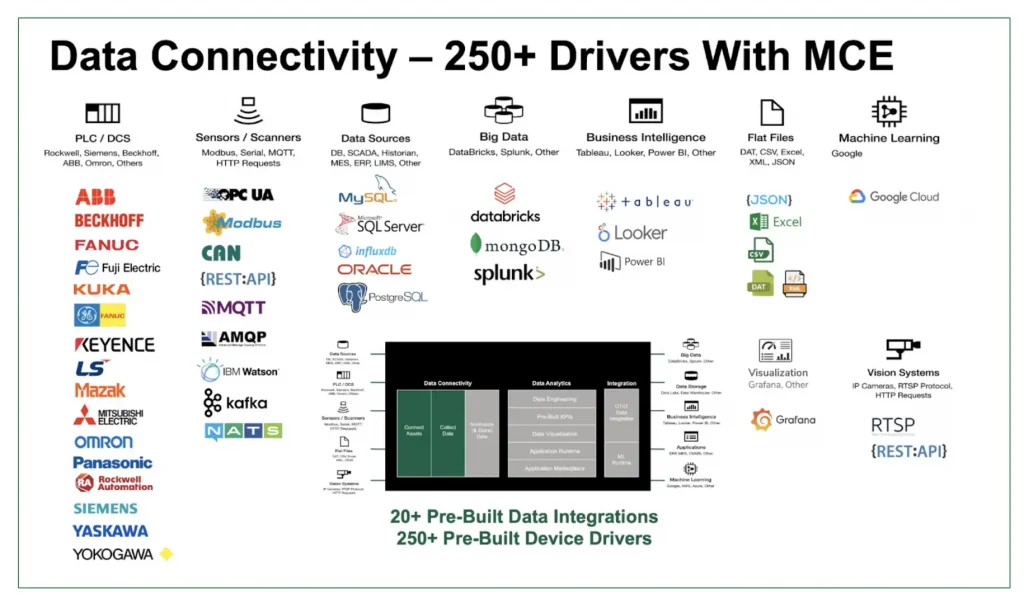

MCE comes with an inbuilt library of 250+ supported machine protocols that can connect into thousands of industrial assets like sensors, PLCs, SCADA, MES systems of different make, model and version. This is one of the biggest differentiator of the platform.

Some of the large conglomerates in India have been able to use MCE to connect into PLCs that were extremely dated. Using MCE, they are now able to leverage the data that was not accessible for years and include these assets into their Industry 4.0 initiatives.

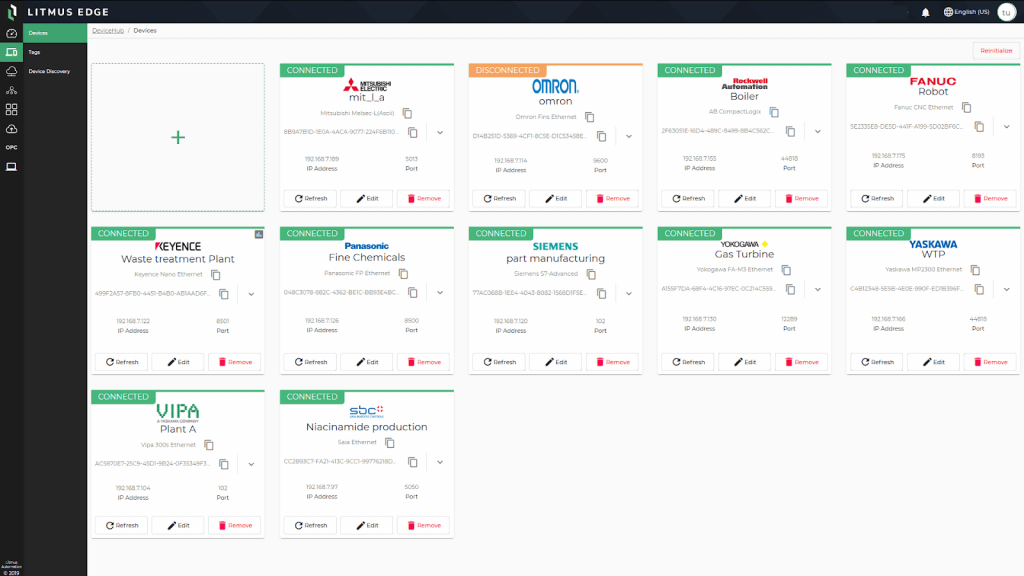

Intuitive UI for Connectivity:

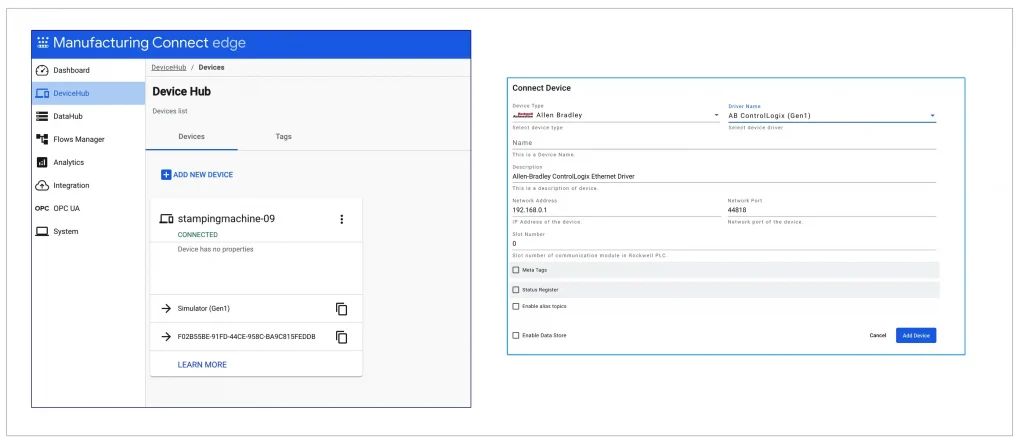

MCE provides a complete no-code portal to configure connection to the Industrial assets and set up all the tags within the asset.

Enclosed is an example view of the MCE portal. The “DeviceHub” section allows adding new device to the MCE platform by entering Device Type, Driver IP and Port.

The DeviceHub as the name suggests, becomes a hub of all the connections to the various assets of plant. Once connected, the device shows a green Connected status as shown below. The UI also provides a stop and start option at the device level.

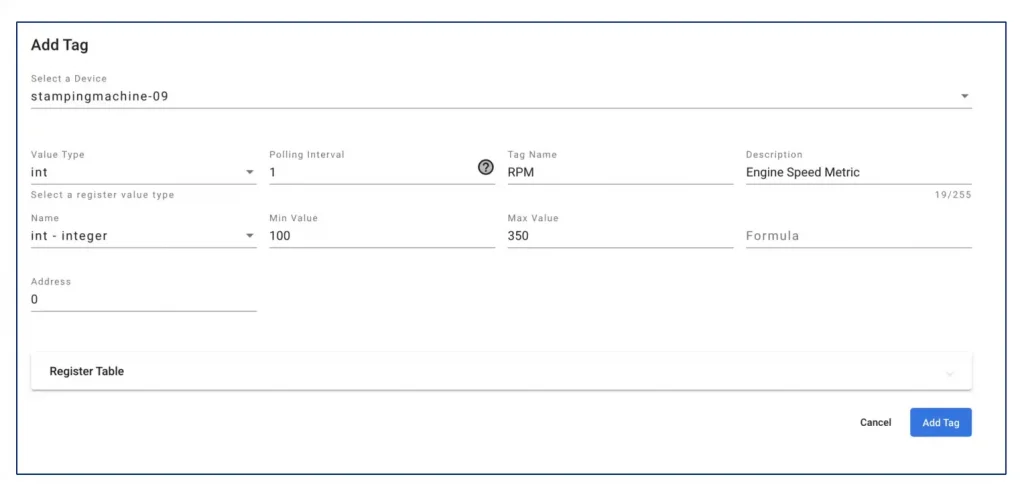

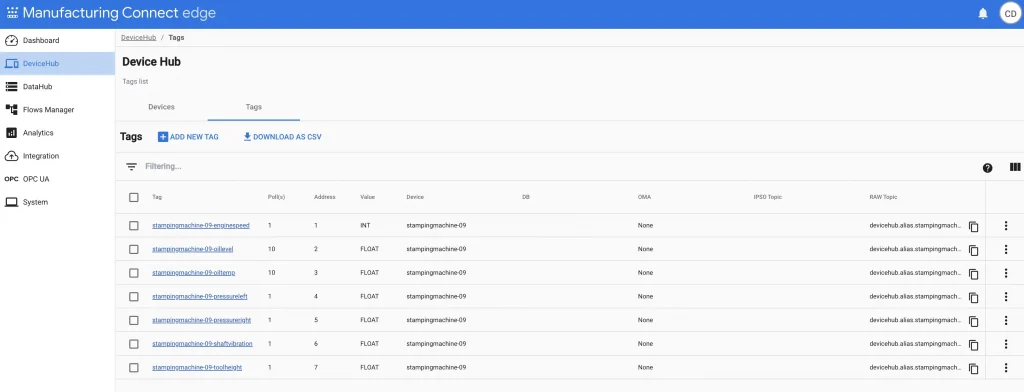

Tags: Once the devices are set up, all the tags specific of particular device (e.g Body Stamping m/c shown below) can be added either one-by-one or can be uploaded in bulk as a csv file.

Each tag can be assigned its own messaging topic where the IIoT payload will be delivered.

In summary, MCE provides an extremely easy to use UI to set up Assets and Tags and connect them through 250+ out-of-the-box connectors.

2. Edge Intelligence:

Edge Intelligence provides the core Data and AI capabilities inside of MCE. Following are the key components of the platform that drives intelligence on the factory floor.

- Local Storage: The storage layer consists of native messaging broker system. All the tags configured in the Connectivity section, can be configured to deliver the IIoT payloads to their corresponding Topics. MCE also provides InfluxDB Timeseries database to store data locally.

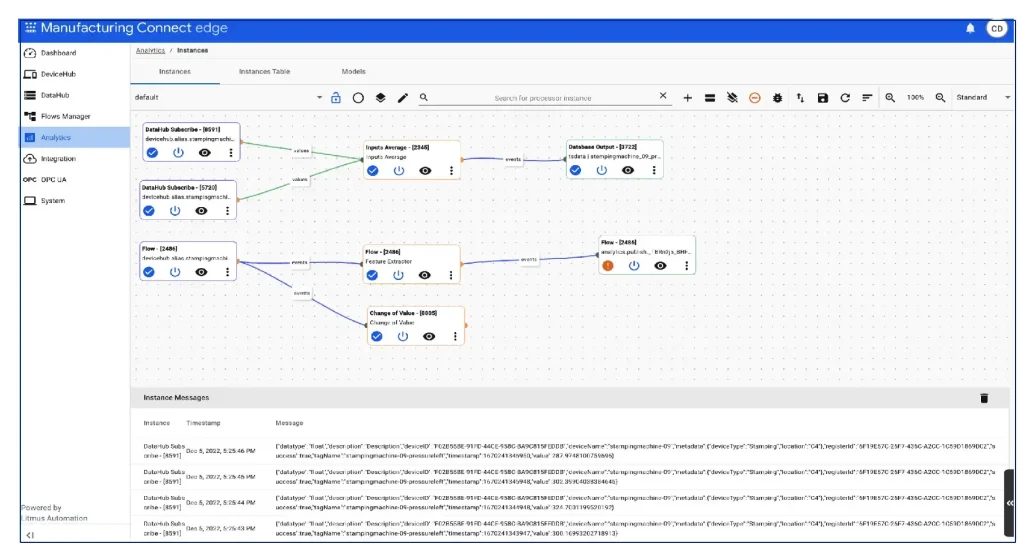

- Data Processing: MCE provides a rich UI based, no-code Analytics workflow builder much like the ETL tools, to build data pipelines to collect, cleanse, merge, transform and store data. It also provides various inbuilt statistical functions for anomaly detection, Arima filters etc.

- Analytics: MCE allows any dockerized application to be installed on its platform. Therefore, popular analytics tools like Grafana, Nagios etc can be installed and used for Advance analytics. Following are some of the example Grafana dashboards on OEE, Downtime and Anomaly Detection.

- AI-ML: AI-ML models created on Google Cloud platform can be exported and hosted as a Docker containers integrated into the MCE edge. Will cover more on this in part-2 of the series.

In summary, MCE provides an extensive Edge Intelligence Platform to collect, store, process, analyze and visualize plant data to power Analytics and AI at scale on the factory floor.

3. Seamless Google Cloud Integration:

MCE fully integrates with Google Cloud platform and provides a complete end-to-end, Edge-to-Cloud solution for building and deploying Industry 4.0 case studies at scale.

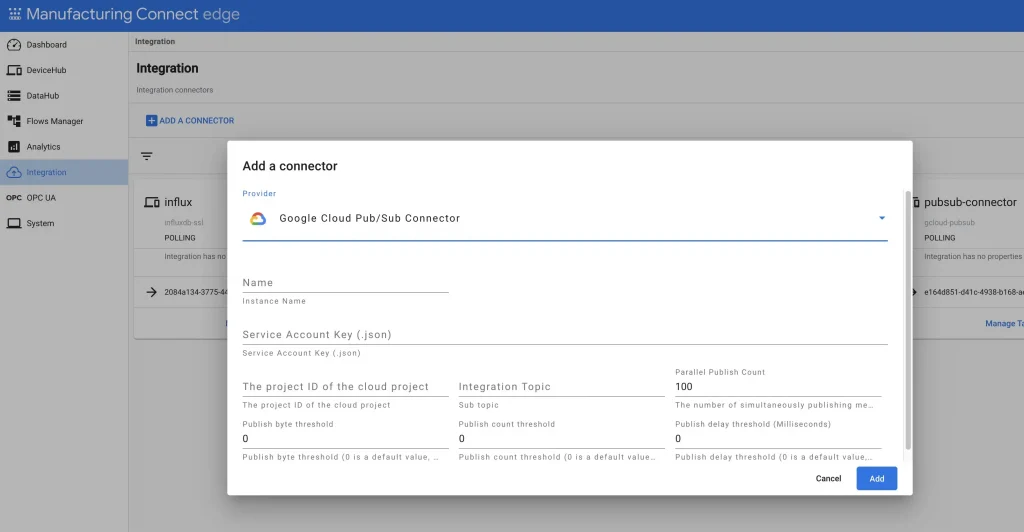

The “Integrations” tab allows creating an integration with Google Cloud PubSub through an easy to use UI. Once the integration is set up, MCE Edge Topics can directly be mapped to the Google Cloud PubSub topics either one-to-one, or one-to-many as required. This will allow seamless flow of the IIoT data from Edge-to-Cloud.

MCE also provides a toggle switch at each Tag to select if the user wants to send data to the cloud or just keep it within Edge.

Once data flows into PubSub — it is available for the rest of the Google Cloud ecosystem for Advance Analytics and AI.

Completing the picture!

True to the title of this blog, here’s the complete picture of the end-to-end, Edge-to-Cloud Enterprise grade Google Cloud Manufacturing Solution!

Stay tuned for the Part-2 of the series which will focus on the most fundamental element of the solution — Google Cloud – Data Engine.

Conclusion:

Google cloud’s new manufacturing solution provides an integrated solution to solve for complex manufacturing challenges at scale. The emphasis is on making critical technology, such as Cloud and AI, accessible, easier to use and deeply embedded in manufacturers’ day-to-day operations, to un-cover new insights and to optimize operations in entirely new ways.

For more details please visit: https://cloud.google.com/solutions/manufacturing-data-engine

The original article published on Medium.